A so-called 80-percent receiver is an AR-15 lower receiver that is 80-percent finished. Depending on the material and the manufacturer, you can finish them yourself using tools ranging from a mill to a Dremel tool. In addition to the satisfaction of “doing it yourself,” an 80 percent lower can be shipped straight to your door with no FFL involved because it’s not a “firearm” until the machining is finished. Because it’s not a firearm, there is no serial number.

According to ATF, “Firearms may be lawfully made by persons who do not hold a manufacturer’s license under the GCA provided they are not for sale or distribution and the maker is not prohibited from receiving or possessing firearms.” That means you can finish these lowers for your own use. You can’t finish one and give it to someone, and your machinist brother-in-law can’t finish your receiver for you.

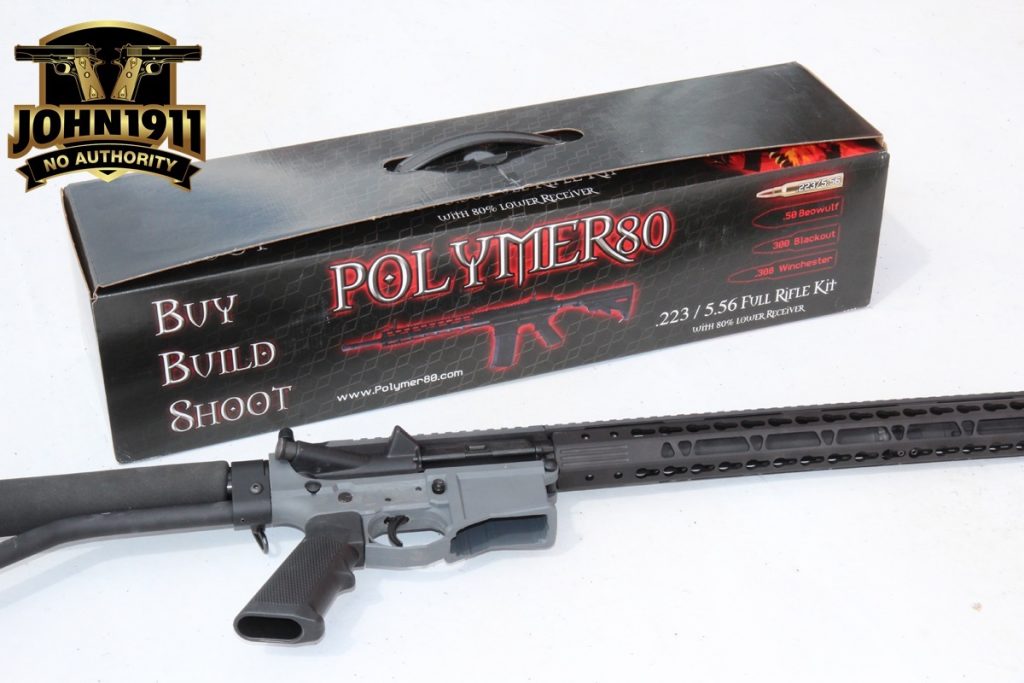

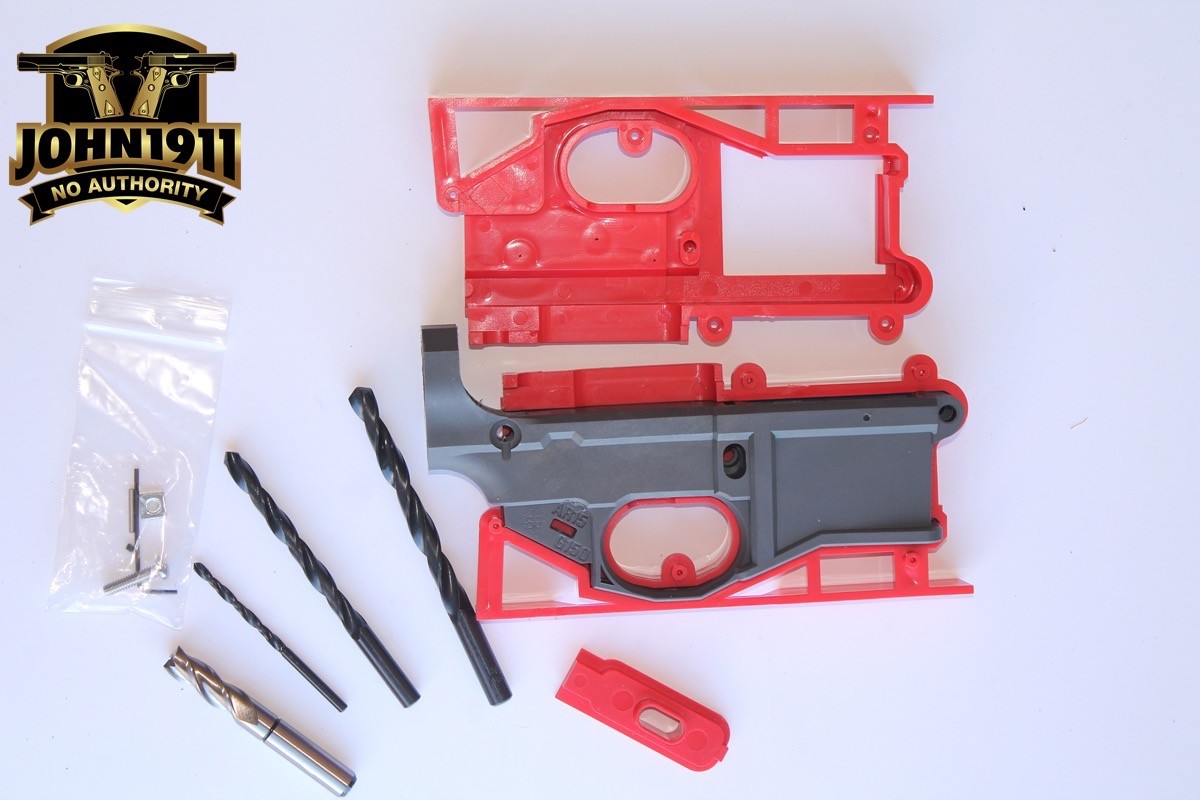

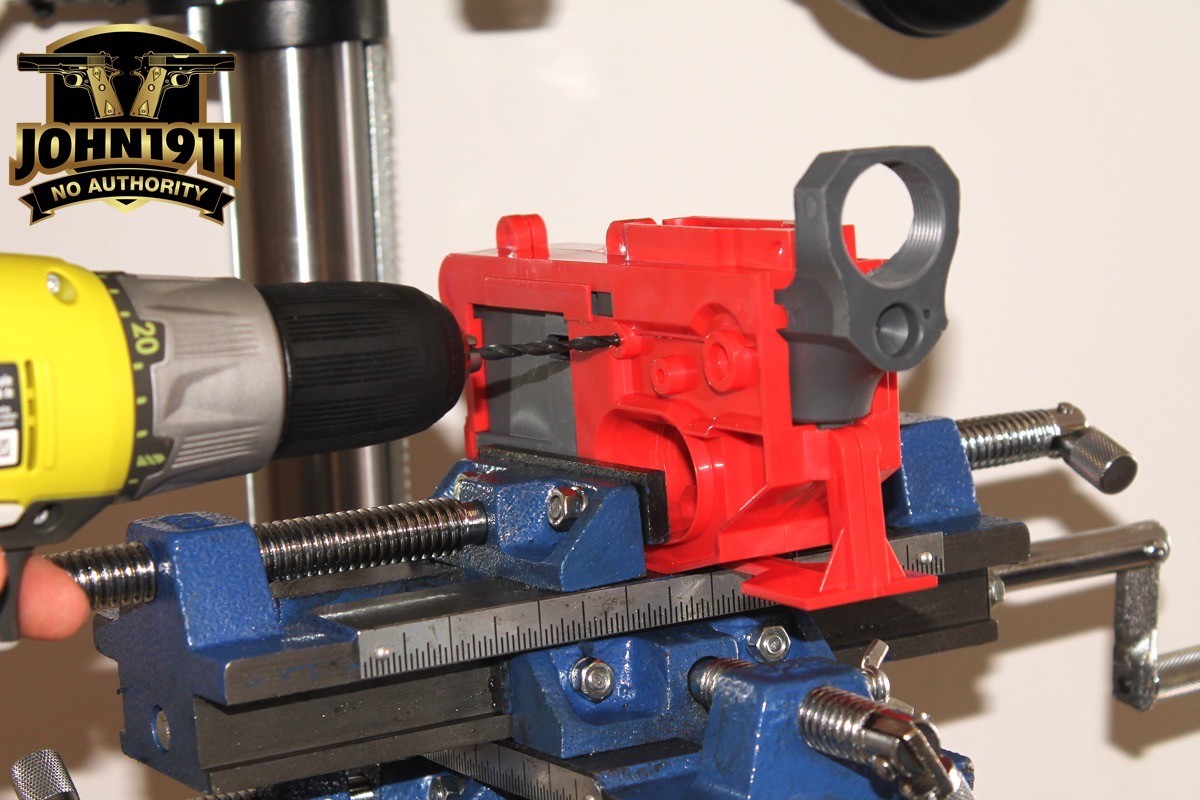

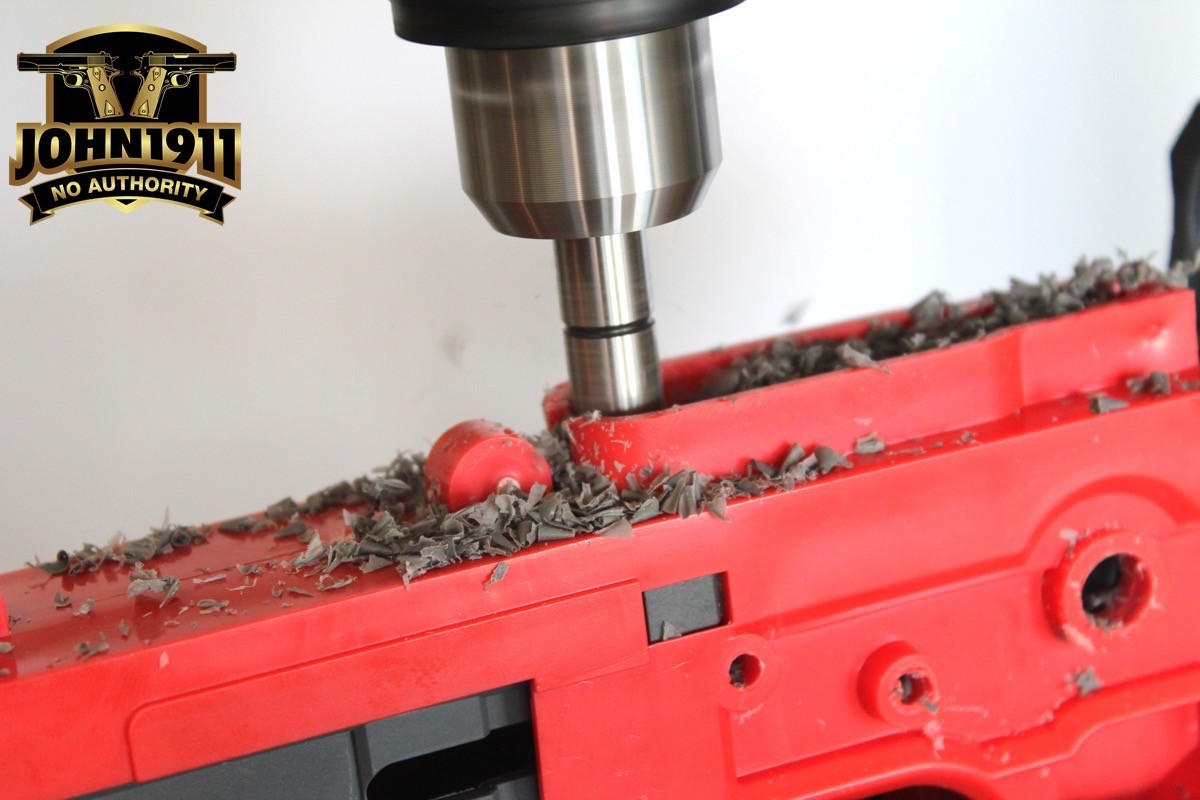

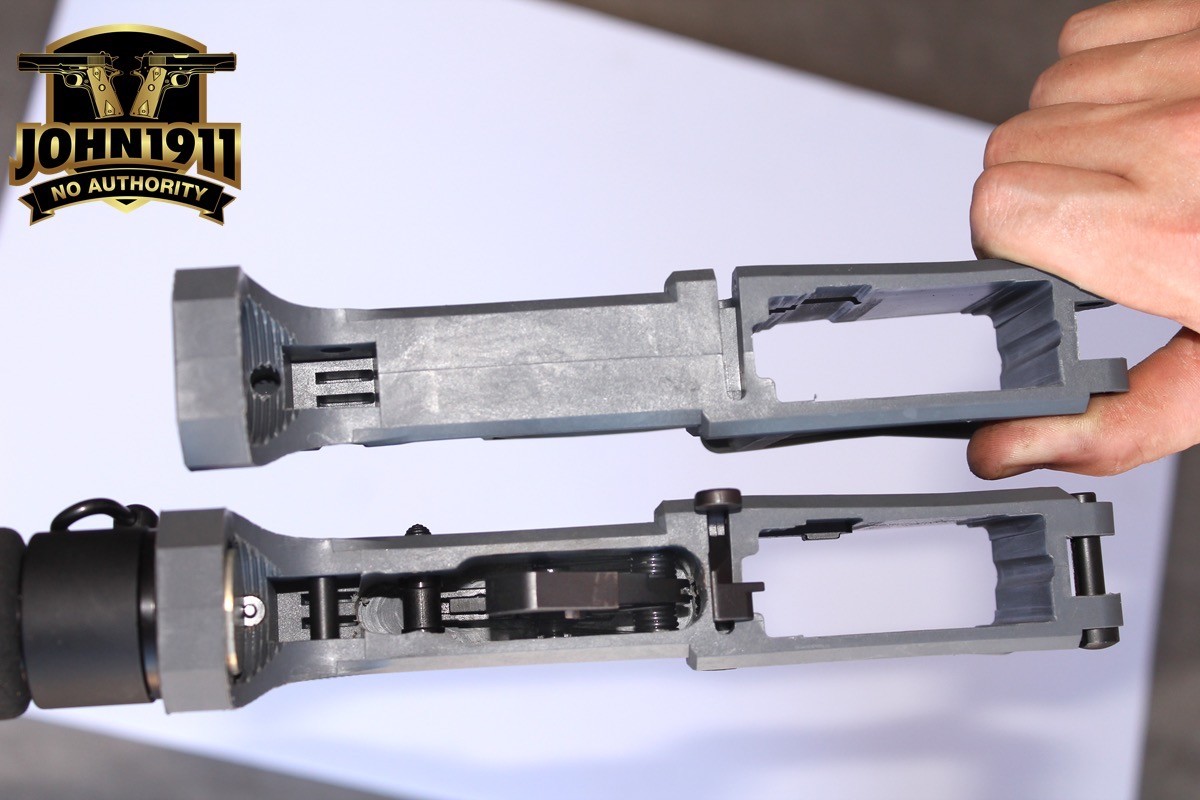

Polymer80 recently came out with what they call the “Buy, Build, Shoot Kit” and it makes completing an AR-15 from an 80-percent lower stupid simple. Every part you need is in the box, including the correct drill and milling bits and an idiot-proof jig so you make your cuts in the right places.

It took me less than an hour to mill out the remaining 20 percent of the Polymer80 lower and then using simple hand tools had a functional and accurate AR-15 on the range by the end of the day. I did take it apart later and give it a rattle can coating of Brownell’s AlumaHyde.

Accuracy is right at one inch at 100 yards, which is right up there with my Bushmaster, and the trigger pull is right there with other rack-grade ARs I’ve handled. Overall, I’m impressed with how easy it was to make this gun. I can never sell it, but why would I?

Scott Mayer

www.john1911.com

“Shooting Guns & Having Fun”

- CMMG Banshee & DefCan - April 13, 2018

- Cartridges Before There Were Cartridges - May 7, 2017

- Gas Rings Seal Test - April 17, 2017