With the recent discussion regarding Colt Pythons, here are my two new-model Pythons; one 4.25” barrel and the other 3”. For years I’ve been looking for a reasonable used Python, one that was usable without destroying crazy collector value. Colt’s re-release was just the ticket.

Initially I bought the 4.25” early after their release (more on that to follow). Later I scored a great deal on this 3” model which quickly became my favorite of the two. The 3” is great to shoot and quite pleasant to carry in a Galco leather IWB holster. It’s certainly not the most practical thing to carry, but with a good belt it rides well at 3 o’clock. Along with the wheel gun, I carry Safariland Speed Strips for “faster” reloads. In the past I’ve had varying luck with the HKS speedloaders. They’re cheap and probably the most available, but they do have their drawbacks. Following Kraken’s advice, I ordered Safariland’s Comp II speed-loader as well. After a bit of fiddling around to figure it out, the Comp II has quickly become my favorite.

Now back to the 4.25” Python. I haven’t run this revolver hard, just plinking at the range and running some steel. Initially I had no issues with about 300 rounds of mixed ammo. This was over a couple of trips to the range before I put it back in the safe for awhile. When I brought it back out for more plinking, I started to notice a few failures to fire. This started becoming increasingly common and clearly an issue. I tried changing primer brands as well as different factory ammo, but the problem persisted. Additionally I numbered my cylinder with marker to identify a potential problem chamber, but the issue was seemingly random. Lastly I brought out two or three other wheel guns to test the ammo. All of the rounds that failed to ignite in the 4.25” Python functioned fine in different guns.

From what I’ve read so far, it sounds like this issue may have plagued the early production new model Pythons, but I’ve yet to confirm that with Colt. I’ve had zero issues with the 3” Python, which was produced in 2023. Potentially, the early production gun’s firing pin does not protrude far enough for reliable ignition, or the mainspring is too light. I’ll be calling Colt to see what their remedy is, and I expect this revolver will be taking a trip back to the factory.

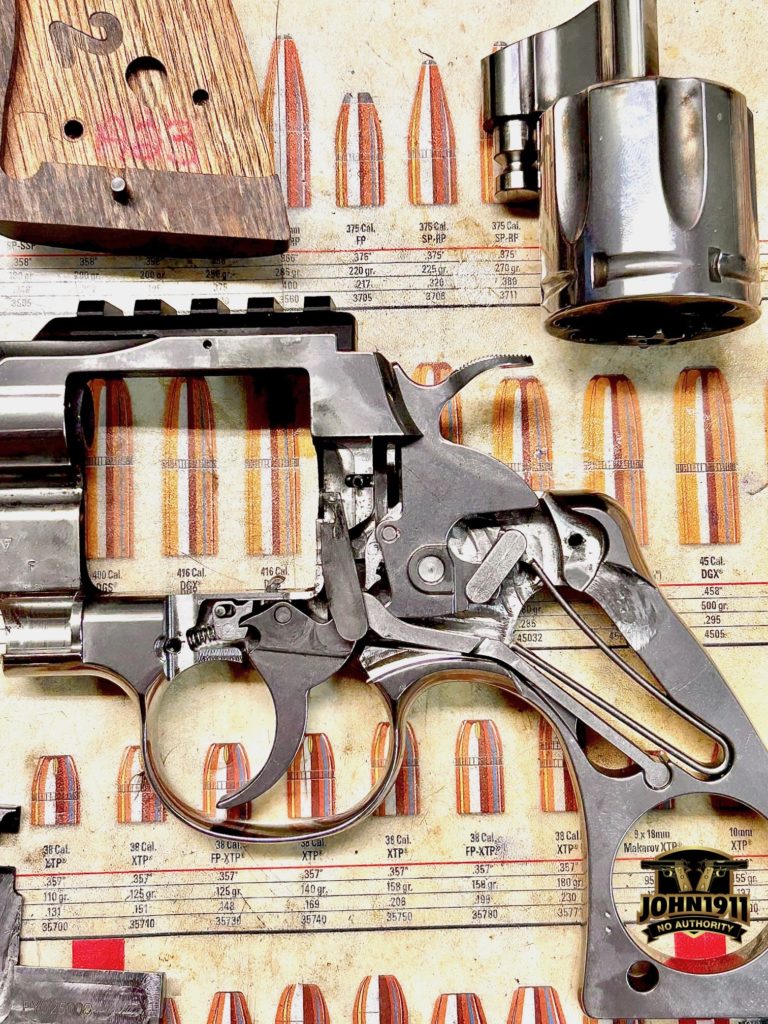

In the meantime, I decided to disassemble the Python to look for obvious problems and give it a thorough cleaning. This was more of a learning experience as I’ve never disassembled any Colt revolvers. All of my experience revolves (ha) around S&W.

As it turns out, the new Pythons are relatively easy to disassemble/reassemble with some notable differences compared to Smiths. First, the cylinder latch isn’t held on by a screw, but instead it’s dovetailed into the side-plate. It isn’t hard to remove or install, but it takes more finesse than latches on S&Ws. Second, there isn’t a strain screw that can be removed to take tension off the mainspring. I’m certainly not an expert, but the best way I found was to squeeze the mainspring in order to provide clearance for removal/installation. Without an old Python on hand to compare, the new Pythons seem quite simple and overall very similar to K-Frames.

Chris

“Shooting Guns & Having Fun”

- October 2025 Moose Hunt - December 21, 2025

- M1A Adjustable Spindle Valve - November 8, 2025

- Custom Taurus – “Not a Colt” - June 12, 2025