Would you believe me if I told you that there’s a good chance you’ve been cleaning your rifle’s bore wrong? “Wrong” might be too harsh a word considering there are so many ways people successfully clean rifle bores. While I won’t argue with anyone’s technique or preferred products, I’d wager that most shooters jump right in and start attacking the copper fouling first and that’s the “wrong” part.

I get it. We’ve been trained that copper fouling degrades accuracy and you can often even see little streaks of it when you look down the muzzle. Copper fouling does degrade accuracy, and you should remove it when it gets to be a problem, but more realistically it’s the carbon fouling you need to be attacking on a more routine basis.

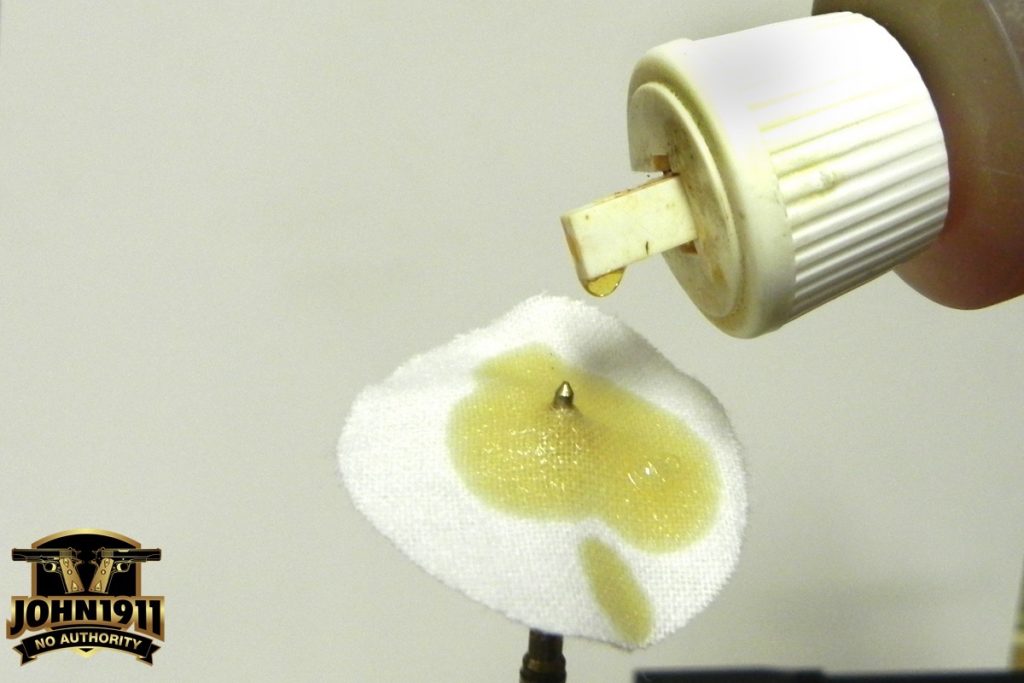

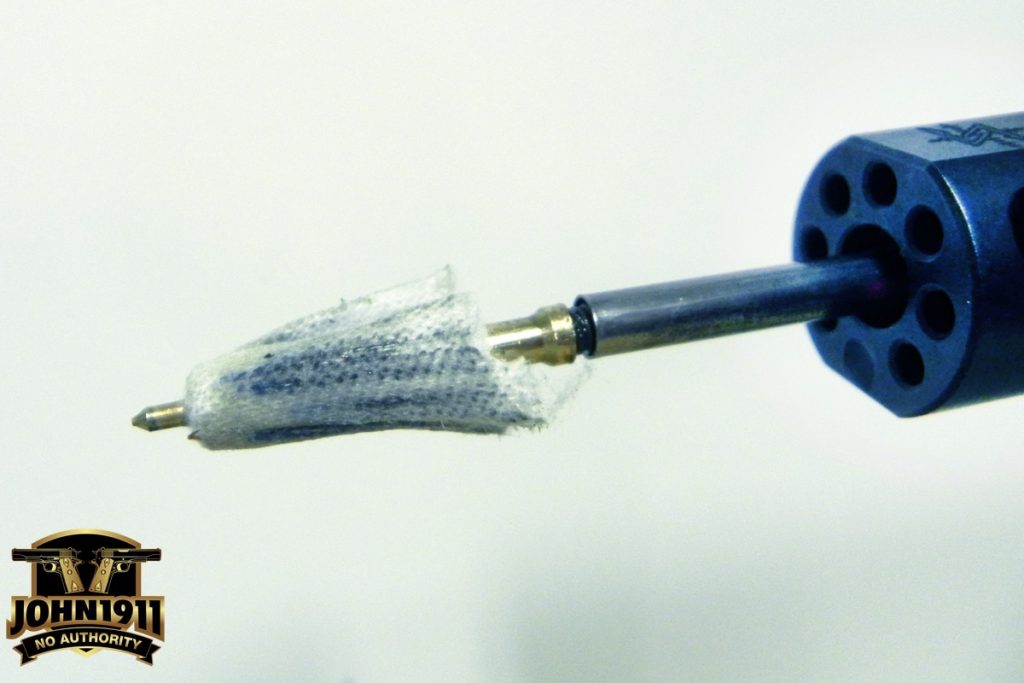

My cleaning regimen is pretty simple and works quickly. I always clean from the chamber end and start with pushing a few patches wet with carbon solvent down the bore. Lately I’ve been using Hoppe’s Elite, but I’ve also used M-Pro7 and homebrewed Ed’s Red in the past. After letting the bore soak for a couple of minutes, I use a tight-fitting clean patch to push out all the loose gunk.

Next, I use a nylon bore brush and the carbon solvent and give the bore a good end-to-end scrubbing, sometimes adding more solvent to the brush while it’s sticking out the muzzle so the whole bore is good and wet. Some shooters balk at pulling the brush back through the bore and instead unthread it at the muzzle, reattach it and push it back through from the chamber end. Their thinking is that the brush can wear the muzzle crown and degrade accuracy. If you’re shooting a gun that groups in the zeros, OK, think about it, but for everyone else if it makes you feel good to take the brush off each time then go for it. I don’t bother.

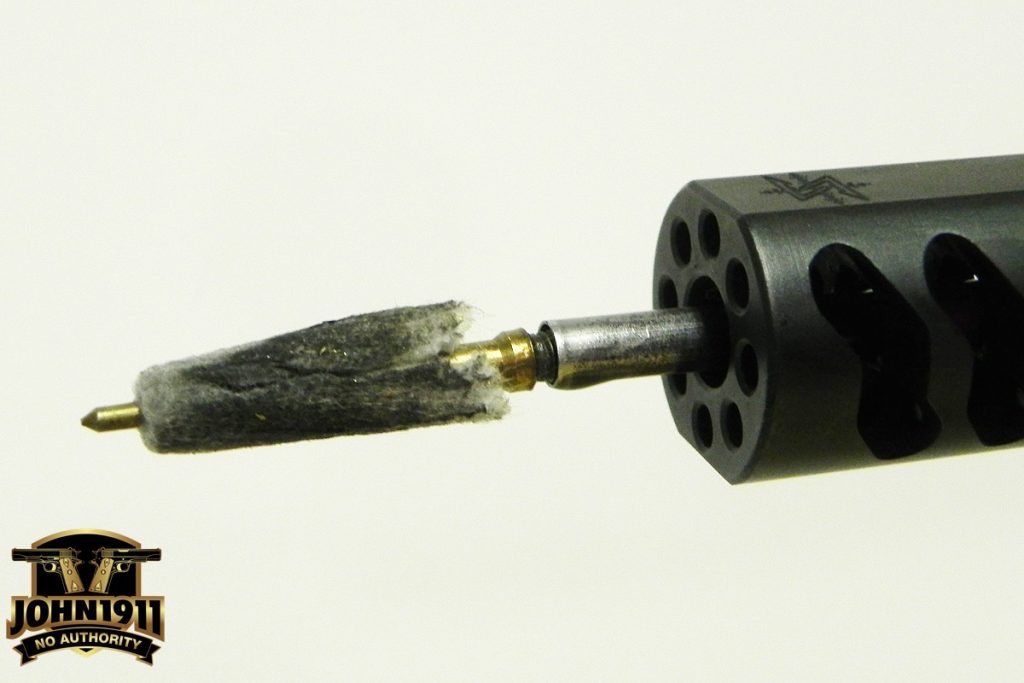

After brushing with carbon solvent, I again let the bore soak a couple of minutes and then alternate wet and dry patches until they come out clean. At this point, the carbon should be clean from the bore leaving any copper fouling exposed for a copper solvent. You probably could stop cleaning at this point and just pass a lightly oiled patch down the bore for short-term storage.

If I want to get the copper out, I run several patches wet with copper solvent down the bore to wet it, and let it soak for a few minutes. I’m using Hoppe’s Copper Terminator as my copper solvent lately, but I’ve also used Montana Xtreme or Sweet’s 7.62 with good results. I follow the soak with one tight-fitting dry patch and then alternate between patches wet with copper solvent and dry patches. When those come out clean, I finish things up with a couple of alternating patches of cleaner/degreaser and dry patches followed by a lightly oiled patch for short-term storage.

Bottom line—get the carbon out first.

Scott Mayer

www.john1911.com

“Shooting Guns & Having Fun”

- CMMG Banshee & DefCan - April 13, 2018

- Cartridges Before There Were Cartridges - May 7, 2017

- Gas Rings Seal Test - April 17, 2017