It’s Past Time To Start Casting Your Bullets

Growing up I was captivated by the accounts of the late Col. Harrison and his experiments with cast bullets in high-power centerfire rifles. Performance there is tough to accomplish, but for handgunners the bar is set much lower and with ammo still being scarce and expensive, you really should consider setting up to cast and load your own not only to get through the rest of this tough patch, but so you’re still shooting a lot during the next.

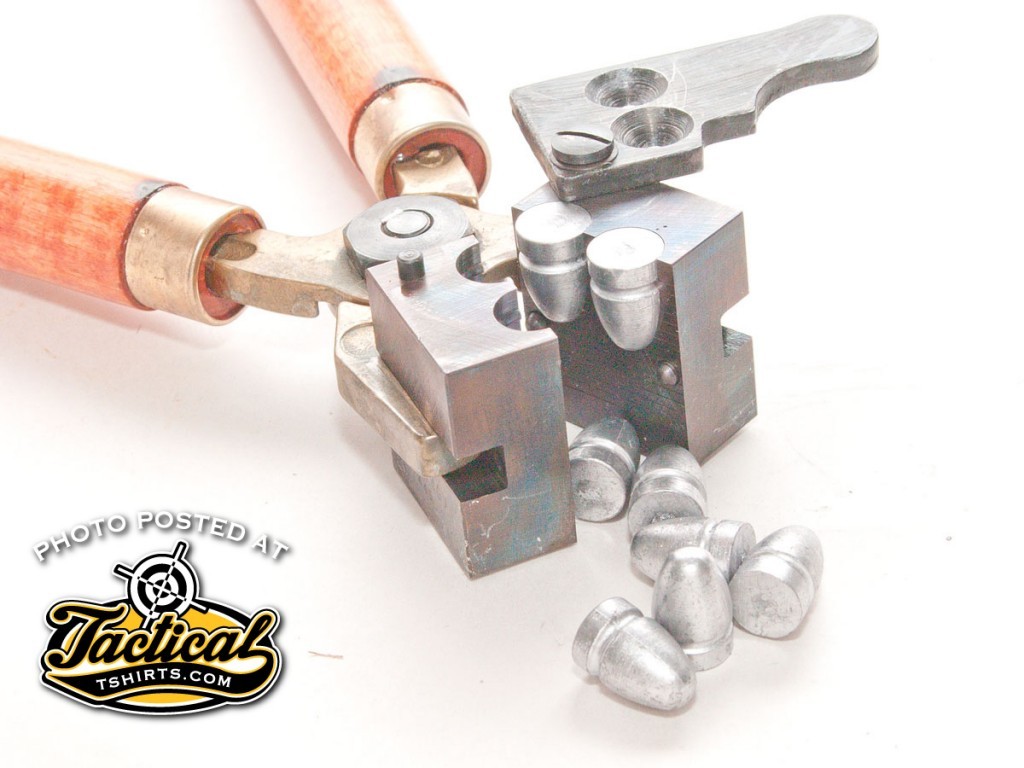

The equipment you need consists of a lead furnace, bullet mold, and sizing/lubricating tools. Getting set up for only one caliber can knock you back as much a grand, or as little as $100, and fortunately even the cheaper bullet casting equipment is good and will last so long as you don’t abuse it. Lead is cheap, and you can get it from most scrap or salvage yards. One warning–don’t use lead plates from lead-acid batteries. They give off a poisonous gas when melted.

- The RCBS bullet lubricator/sizer is one of the best tools of its kind on the market. It takes different size dies for different size bullets and lubricates bullets as part of the sizing process.

- A 0.385-inch die is usually used to size bullets for .357 Mag. or .38 Special.

The process is simple. Melt the lead, heat the mold, get the lead into the mold and you have a bullet. That bullet comes out of the mold as bare lead and a little over-size, so you have to run it through a die that sizes the bullet down and forces lubricant into the groove around it. After that, it’s ready to load.

- With cast bullets, you can shoot a lot more for less money. Note that some manufacturers recommend against cast bullets.

You can keep bullet casting that simple, or advance and discover a whole world full of really cool ways to experiment for different levels of bullet performance. For example, you can change how hard or soft the bullets end up by using different lead alloys, quenching or air-cooling, or age hardening. You’ll find that you will get better (or worse) accuracy by tweaking the size of the bullet in 0.001-inch increments, and that different lubes can change the accuracy of a load. Either way, you end up shooting a bunch more, and that’s what counts.

- Cast bullets are often really accurate. This group was fired using bullets cast from a mold that currently sells for $20.

- This is the author’s favorite .45 ACP cast bullet. They basically replicate the classic 230-grain Hardball.

Scott Mayer

www.tacticaltshirts.com

“Shooting Guns & Having Fun”

- CMMG Banshee & DefCan - April 13, 2018

- Cartridges Before There Were Cartridges - May 7, 2017

- Gas Rings Seal Test - April 17, 2017