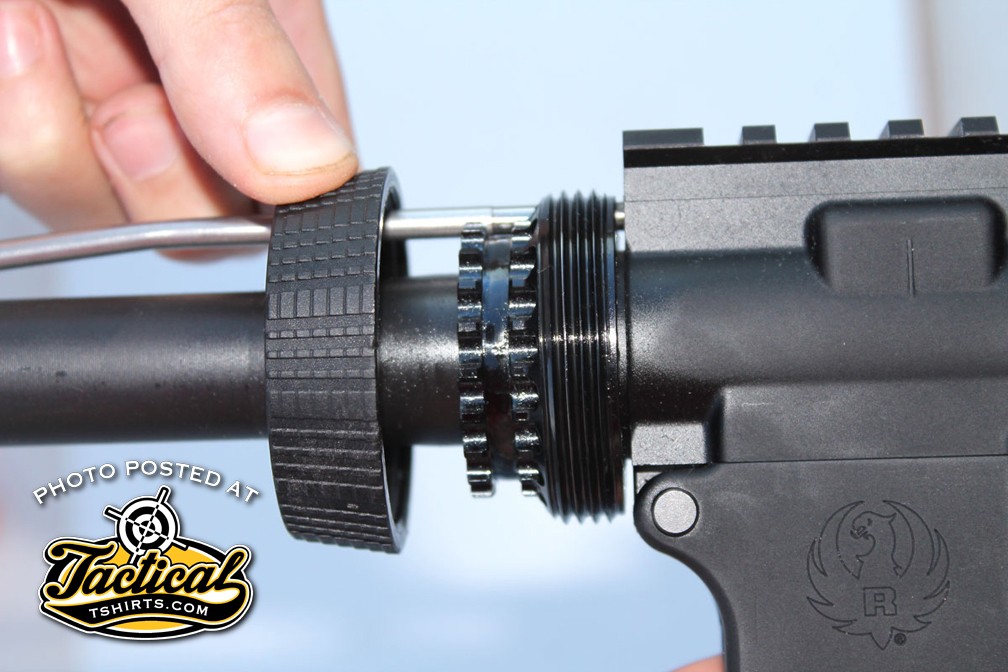

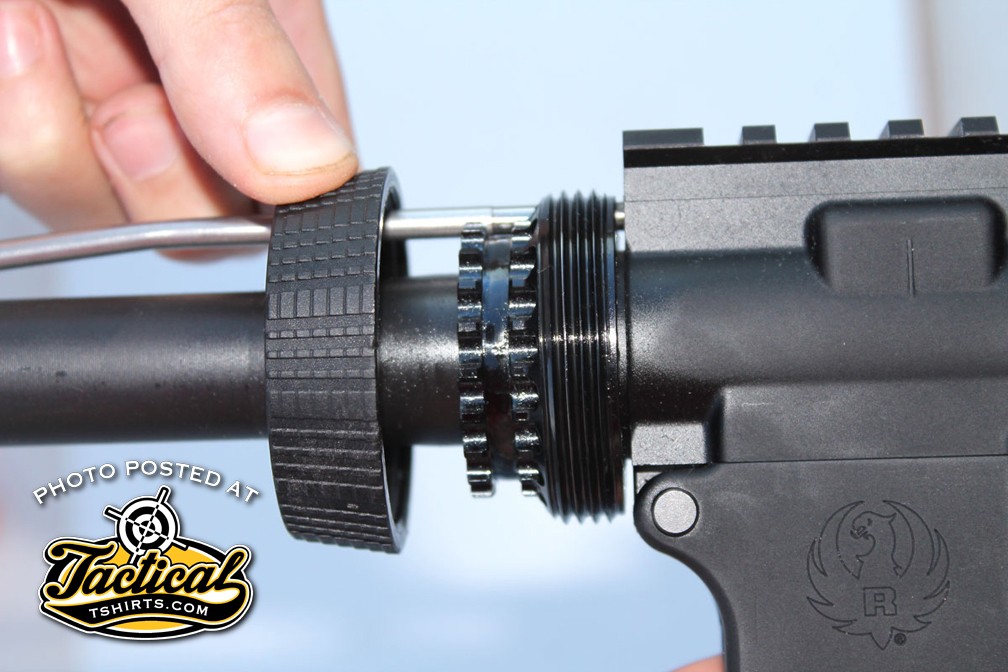

Last year, Ruger came out with its new AR-556 rifle. The gun is a very basic direct impingement (DI)-type AR-15 with a suggested retail of $749. It’s Ruger’s first DI M4, and the first gun made at the new Mayodan, NC plant. Despite being a basic gun it’s a full-featured AR. It has the brass deflector, dust cover and forward assist that other companies drop from basic guns to hit an entry-level price point. It also has enhanced features such as flip-up rear sight and six-position buttstock. All that’s great, and the gun I tested shoots one-inch groups at 100 yards, but the one feature that I really like is how Ruger treated the delta ring on the AR-556.

If you’ve ever tried to change the fore-end on an AR, you know it’s a three-hand job at best. It takes both hands to compress the delta ring and a third to pry off the fore-end halves. What Ruger did was, instead of having the delta ring spring-loaded, they threaded it. “The nut was a selfish move–it made the gun easier to build on the line by one person,” says Ruger’s long gun product manager, Mark Gurney. When I’ve shown the new ring modification to others on the range the response is that the modification is obvious in hindsight. Shooters like that can still use any handguard on the AR-556, and that it’s easier to change.

Kudos to Ruger for making such a minor tweak with such significant impact while staying true to the original AR-15.

Scott Mayer

www.tacticaltshirts.com

www.john1911.com

“Shooting Guns & Having Fun”

- CMMG Banshee & DefCan - April 13, 2018

- Cartridges Before There Were Cartridges - May 7, 2017

- Gas Rings Seal Test - April 17, 2017