I look at how body armor technology has changed in my lifetime and then wonder what amazing discoveries will be coming over the next 40 years? Clear metal? Force Fields? Who knows? –Marky

While the U.S. Navy is busy with the development of a new bulletproof material called Spinel, Surmet Corporation is already commercially producing its own version called ALON®.

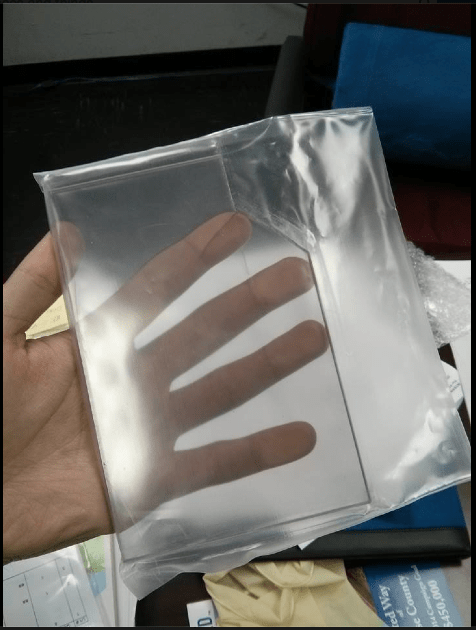

Developed by Raytheon, ALON or aluminum oxynitride, begins as a powder, which is then molded and baked in very high heat. The heating process causes the powder to liquefy and cool quickly, leaving the molecules loosely arranged, as if still in liquid form. It is this crystalline structure that provides ALON its level of strength and scratch resistance comparable to rugged sapphire. Polishing the aluminum oxynitride strengthens the material and also makes it extremely clear.

Comparing Aluminum Armor to Traditional Bulletproof Glass

Traditional bulletproof glass is comprised of multiple layers: polycarbonate sandwiched between two layers of glass. Similarly, transparent aluminum armor is also composed of three layers: an outer layer of aluminum oxynitride, a middle layer of glass and a rear layer of polymer backing. However, the similarities stop there.

Aluminum armor can deflect the same rounds from small-caliber weapons as traditional bulletproof glass, but it will still be more clearly transparent even after being shot. Also, a .50-caliber armor-piercing bullet could sink nearly three inches into bulletproof glass before stopping. Aluminum armor can stop it in half the distance and yet is half the weight and thickness of traditional transparent armor.

In addition, transparent aluminum armor can be produced in virtually any shape and can also hold up to the elements much better than traditional bulletproof glass, which can be worn away by blowing desert sand or shrapnel.

Despite aluminum oxynitride’s ability to produce a superior transparent aluminum armor, this material has not been put into widespread use. The largest factor in this is cost. Transparent aluminum armor can be anywhere from three to five times as much to produce as traditional bulletproof glass. In theory, however, it would not need to be replaced as often, saving money in the long run. Further, there is no existing infrastructure to produce the material in large panes like the size of a front windshield of a vehicle. ALON is currently used for smaller applications, such as the lenses in battlefield cameras or the windows over the sensors in missiles.

- EP-345: Did KeyMod Save President Trump? - July 18, 2024

- EP-344: The Commies Get Their Wish…Kinda - July 15, 2024

- EP-343: Donald Trump Shot - July 14, 2024